Developing a recyclable recycling plant and creating a production line for frames and shutters that will use the products of the first business

Acronym |

PANEURO |

| Project Number – MIS | 5104599 |

| Priority axis | 1 - A Competitive and Innovative Cross-Border Area |

| Investment priorities | 3d - Supporting the capacity of SMEs to grow in regional, national and international markets, and to engage in innovation processes |

| Intervention fields |

064. Research and innovation processes in SMEs (including voucher schemes, process, design, service and social innovation) |

| Call | 5th CALL FOR PROPOSALS |

| Lead Beneficiary | PANTELIDIS FIL GERASIMOS & PARTNERS O.E. / ALUPAN |

| Beneficiaries |

EURO DECK SYSTEM LTD |

| Start Date | Dec 21, 2020 |

| End Date | Dec 20, 2023 |

| Budget | 516.635,18 € |

| ERDF Contribution | 285.440,94 € |

| National Contribution | 50.371,93 € |

The investment plan refers to two production companies, which will be able to enter the market, facing successfully the challenges of the business environment. They will cooperate in their local and national markets, while at the same time finding common paths that complement each other. The business of Bulgaria, in the sensitive field of waste management for recycling and, in particular, to the recovery of recycled materials, is moving forward to the investment project with a Greek company which manufactures roller blinds and shutters from aluminum with the use of components resulting from the recovery of recycled materials of the Bulgarian business. The culture of cooperation is going to be consolidated and takes steps forward through joint participation in exhibitions.

Downloads

PANTELIDIS FIL GERASIMOS & PARTNERS O.E. - http://www.alupan.grRemodelling of existing building

Works implemented: 1.External and internal thermal insulation; 2.External and internal lime mortars; 3.Exterior and interior coloring; 4.Roof waterproofing; 5.Placing tiles; 6.Installation of external frames; 7.Installation of internal frames; 8 heat pump installation

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Installation of a hanging shed 9.00 by 5.50 meters by contractor but using οwn metal elements, for the receipt of raw materials and dispatch of finished products unhindered by weather conditions

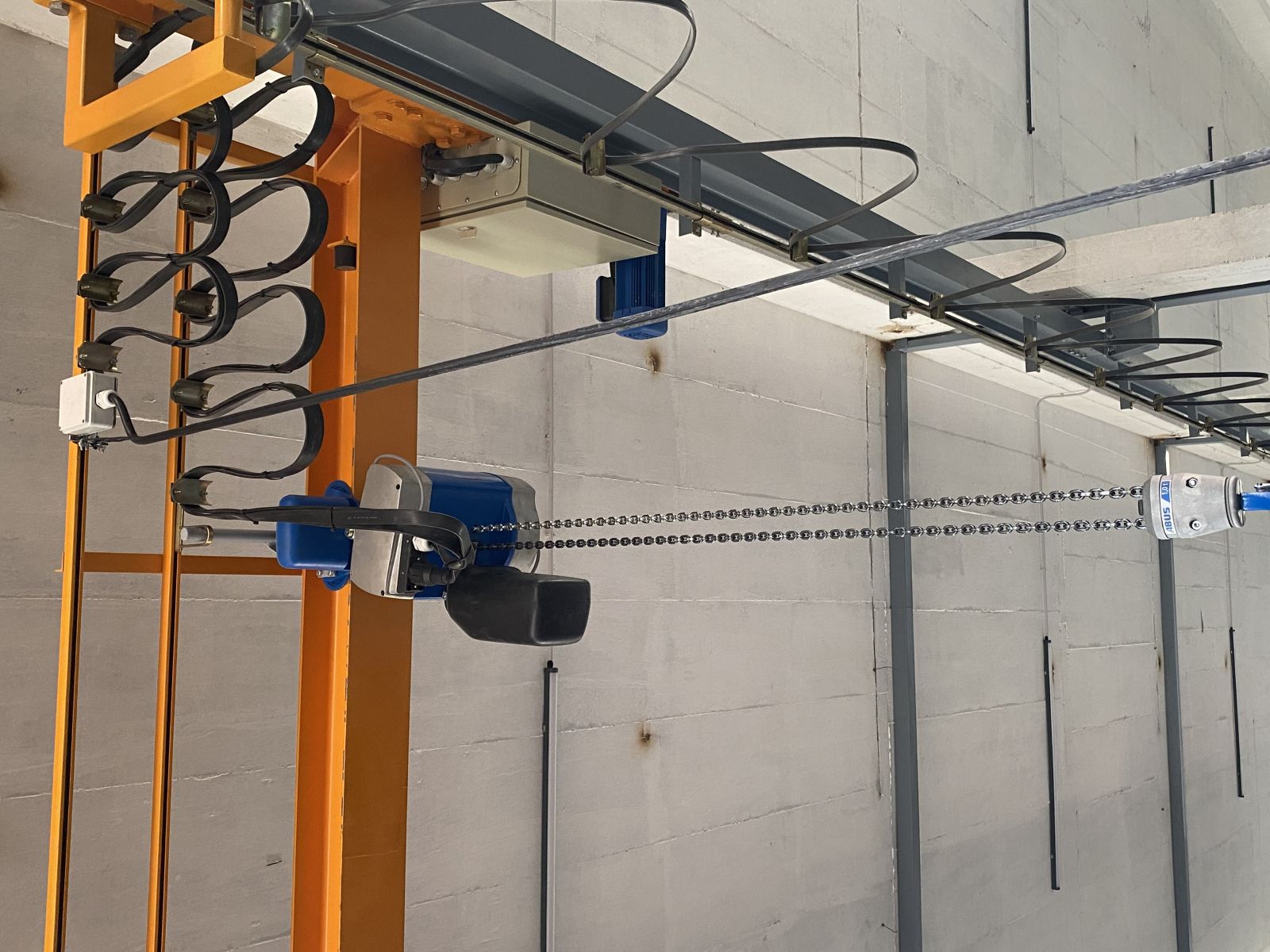

New (ICT) machinery and equipment

.jpg)

.jpg)

Installation of a small photovoltaic unit 10 kWp on the roof of the building for the company's contribution to the low environmental footprint as well as saving energy in its electrical consumption

.jpg)

Transport vehicles and equipment

.jpg)

.jpg)

.jpg)

.jpg)

Application of the ISO 9001 & ISO 14001 standards in the company's production process as well as compliance of the final products with the written provisions of the corresponding CE

Participation in KAVALA EXPO, 2. - VIDEO

ET DIMITAR HRISTOV - NETI - http://www.neti-bg.com

New machinery and equipment - One production line for plastic seals (gaskets) by 5 machines 1. one extruder with nozzle of min 60 mm and capacity 40m/min - the extruder provides melting, homogenizing and forming the seals 2. one water immersion cooling system - the formed profile going trough cooling pool for decreasing the temperature to levels suitable for packaging 3. one haul off unit - it pulls the cooled profiles with certain speed set by operator 4. one cutting machine - cut the pulled profiles to the desired lenght 5. one winding unit - it packed the ready profiles to length or weight set by operator.

.jpg)

.jpg)

.jpg)

Purchase of ERP system, a cloud ecosystem of integrated modules and SaaS solutions. Bizzio can be accessed from anywhere in the world with internet and there are no restrictions on working places and users. The ERP system will help to run the entire business.

ISO 14 001:2015, environmental management system in the production of Dimitar Hristov - NETI. It provides businesses with a framework to continually improve their environmental performance in order to cut costs, reduce waste, and show management that they are growing sustainably.